Life With Isle of Harris Distillery: ‘The Hearach is special, it has done so much for the island’

Isle of Harris distiller Thomas Macrae talks to us about his earliest memories of whisky and why The Hearach is so special to islanders. And he takes us through the process of making the dram.

My earliest memory of whisky was my dad and I walking down a few houses to visit a man called Billy that lived in the village. He was an old man with a big beard – similar to our family dog that was named after him. They would spend the evening spinning yarns and enjoying a dram so I’ve always thought of it as a sociable drink. When I was younger whisky definitely wasn’t my preferred drink of choice. But as I got older it began to grow on me and now as a distiller I can appreciate all the effort and time that goes into a good dram.

‘I can appreciate all the effort and time that goes into a good dram’

I finished school on the Isle of Lewis back in 2016 and then went straight to working on my dads fishing boat. Unfortunately I didn’t have the sea legs so after nearly a year of it I figured I was best on land. From there I went on to working in a shellfish factory, then onto working as a Civil Servant for four years. I was always interested in the distillery but I thought you would have needed certain qualifications or studied distilling to become a distiller. When I saw the job application it said ‘training would be provided’ so I figured why not and now here I am.

‘When I was younger whisky definitely wasn’t my preferred drink of choice’

I start work at 7am. If I am on the stills that day I turn on the water pump, cooling tower, air compressors and then the steam from the boiler. Then we get to the distilling. Once we start collecting distillate, after roughly 40 minutes, I would take samples from the spirit safe. I then nose them until I am happy that we have run onto the heart of the spirit, that will end up in a cask. We aim to have a spirit run last four hours which creates a lighter and consistent spirit before switching to the final part of the spirit run, the tails. Then I pump the collected spirit through to the warehouse for cask filling. When spirit run ends I empty both stills into the pot ale tank and clean the wash still before preparing to fill them both up again for the second distillation of the day.

‘The whisky produced here in Harris is special for a lot of reasons’

The whisky produced here in Harris is special for a lot of reasons. The Hearach is the first legalised spirit made in Harris and it has done so much for the island. It has provided nearly 50 jobs here at the distillery. It’s amazing to see bottles of it around the world not just for me as a distiller, but for everyone on the island. It’s a representation of us.

Everyday there is something that needs to be adjusted or tweaked whether it’s the machinery, the recipe, the mill settings or many other variables. Whatever it is, we have to adapt to it and find the best way to maintain the high quality of our spirit.

I finish a dayshift at around 3.30pm. I am learning Japanese just now, I am hoping to visit one day, so after work I do some work on that. Otherwise I am either playing football or finding something to watch on the telly.

Making The Hearach: Thomas talks us through the whisky making process

- Malted barley is delivered and put into our silos.

- 1.2 tonnes of the malt is then put through our mill and crushed to open it up exposing the starch so we can extract the sugars.

- To begin extracting the sugars we mix the milled malt with 4800L of hot liquor that contains some sugars from the previous mash.

- Even hotter water is then sprinkled on top to help wash more sugars off the malt we put into the mashtun and is collected into our washbacks.

- Yeast is added into the washback, this step is the most crucial in whisky making as yeast is what makes ethanol. Once washback is filled to roughly 6000L it is left to ferment for three to five days.

- Once the fermentation period ends it gets distilled twice. Once through our Wash still and then once through our Spirit still.

- Alcohol has lower boiling point than water so once heated up in the Still, the alcohol turns into a gas and travels up the still before cooling down by our condensers and turning back into a liquid now at higher % ABV.

- During the distillation in the Spirit still, the same process occurs except we take cuts during the distillation run. The very start of the run is called the heads which is gathered and recycled. We then go into the hearts which is the spirit that is used to fill the casks, we call this new make spirit. The final cut is the tails which is also gathered and recycled as there is still alcohol present but doesn’t taste as good.

- The New Make gets reduced to cask strength 63.5% and then will go into an ex-Bourbon or ex-sherry cask and taken down to our warehouses in Ardhaisig to mature for minimum of three years turning it into whisky.

Read more from the Life With series here.

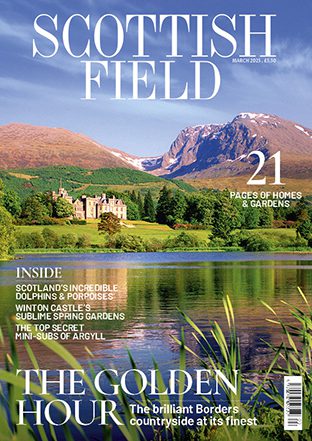

Subscribe to read the latest issue of Scottish Field.

TAGS