So you think you want to open your own distillery?

It seems that barely a month goes by in Scotland without news of another new distillery being created.

It takes guts, the patience of a saint and a considerable amount of cash to get a whisky distillery up and running.

However, unlike many other investments if it all goes wrong, you can also drown your sorrows with your whisky, assuming you managed to make any in the first place before the plug was pulled.

So what will you need?

1. Money.

More than anything you will need a considerable amount of investment to get off the ground. It’s not even worth thinking about setting up a distillery unless you’ve got at least £5 million in the bank, or from investors, but this money will go towards the initial build and set up. You’ll then need around £250,000 per year to keep your distillery running. This would go towards your overheads such as staff salaries, raw ingredients, casks etc.

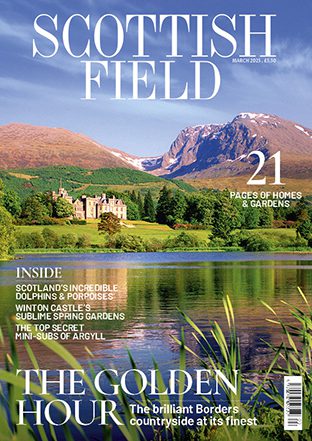

2. Location.

Before you start to even think of where your dream distillery would be you’ll need to make sure that there is a decent and reliable water source for your distillery. This is more important than you might think. Make sure you know who owns the water source as land disputes and litigation would eat into your funds quickly. You’ll also need to be certain that the water supply is consistent all year round. In 2013, Tobermory Distillery had to suspend production due to a drought on the island. The loch that supplied the distillery had only had a fifth of the usual rainfall that year.

The stills are vital in whisky production

3. Distilling equipment

The copper stills for your distillery are likely to be one of your major expenses in the initial setup costs. The go-to place for copper pot stills is Forsyth’s in Rothes. They’ve made the stills for pretty much every single distillery in Scotland, except some of the newer ones.

They also make the stills for the likes of Patron in Mexico, Woodford in Kentucky and Yamazaki in Japan just to name a few. In fact, they are so popular that there is supposdly a five year waiting list.

So, once you’ve decided to set up a distillery you could take the plunge by putting down a deposit, get on the waiting list, and you’ll then have around five years to raise the rest of your investment, build the distillery and by then the stills will be ready to slot in. Bear in mind the size and shape of the stills can make a impact on the final spirit.

A short still will give a heavier, oily spirit while a tall and slender still will produce a softer and lighter spirit. You’ll also need to decide things like if you want wooden washbacks versus stainless steel

4. Raw ingredients

What type of barley will you use? Will you get it supplied by a local farmer? Will you malt it onsite or have it malted by a commercial maltster? Or will you cut out this all together and just buy it direct from a commercial maltster? You’ll also need to think about whether or not you want the malt to be peated and also what variety of barley you’ll want to use. Will you use distillers yeast? Will it be liquid yeast or powdered yeast? This are all important questions you’ll need to think about.

5. Distilling and filling

Let’s assume everything has gone to plan and you are now the proud owner of a fully commissioned and working distillery.

You’ll need to spend a wee while tweaking and finessing things such as: ratios in your grist of your husks, grits and flours, the temperatures for your mashing water, the length of fermentation and then the cut points in your distillation.

Then you’ll need to decide what type of casks you want to fill in bourbon, sherry, wine or other. All of these will make a significant difference to the final whisky but can also make a significant difference to your bank balance for the costs of the casks, with sherry butts fetching sometimes up to ten times the cost of a bourbon barrel.

6. Time.

Your whisky is finally in a cask and waiting in a warehouse. You now need to decide how long you’ll wait. You’ll need to wait an absolute minimum of three years, but you will probably wish to wait longer say five years to make sure the whisky does not taste too immature.

This is partly a game of chicken, will you bottle sooner due to a rapidly dwindling bank balance or will you be able to stay strong and hold off until you believe you truly have hit the sweet spot for your whisky? Daftmill Distillery in Fife started distilling in 2005 and are yet to release a whisky.

7. Cash flow.

What will make or break you is cash flow. You could look at making gin, like many new whisky distilleries have done. Gin can be sold unaged so could be a good source of income, however the market is saturated. You could think about building a cafe into the distillery, which was what Kilchoman on Islay did, and make some revenue from visitors to the cafe, while the whisky matures. Whatever you do you’ll need to have nerves of steel and strong cash flow to keep afloat.

8. Bottling and selling.

You’ve decided to bottle your first whisky, well done! You’ll need to think of things like bottle design and size, branding. But also you’ll need to consider things like bottling strength, will you go for standard 40% alcohol by volume, to get as much from a cask as you can, or will you bottle at a higher abv, but bear in mind you’ll have more duty to pay?

You’ll then need to find wholesalers and distributors. You may wish to hire brand ambassadors and attend whisky festivals. Saying all this, if you’ve been sensible with your overheads you could be looking at around £15 profit on a whisky that costs £45. If you are particular savvy you may in time make a profit. Kilchoman became profitable in year five, which is quite an achievement. Once your whisky takes off and your whisky starts selling out, you’ve hit the jackpot. When you get to this point, as the late Jim Swan said, you now have ‘‘a licence to print money’.

Good luck!

The author and Scottish Field accept no liability for losses or damages if you try to set up your own distillery based on the information above.

TAGS